Case studies

Some examples of where we have worked with our clients to bring their products to life

AV Stands

True North was selected as the production partner for an on-shoring exercise where production was moved from Asia to Europe.

A sheet steel fabrication incorporating aluminium extrusions, with multiple user configurable options. True North began production in 2009 and has been part of the development of new models ever since.

Articulated arms

True North has been selected by one of the world leaders in the design of ergonomic monitor arms to be their key engineering and manufacturing partner. From single screen arms, to multiple screens, to hospital applications (pictured).

We are supplying over 70 different products ranging from complete multi-monitor arms to clamps and fixing kits.

The end user experience and quality perception is based on “feel in use”. We perform rigorous, routine batch testing and have created objective, bespoke test regimes and tolerances to guarantee customer satisfaction.

Desk light

Working with an industry leading design company, True North partnered in the development of this innovative desk lamp. It is a product which uniquely combines the ability to power and charge portable devices with a touch dimmable LED desk light. This arrangement of light, USB and mains has never been achieved before in such a compact offering.

Due in part to the compact size, considerable design engineering input was required by True North in order to achieve the design requirements and be certified for electrical safety in global markets.

Multiple versions are currently in production by True North, with approval marks from UL, CE and GS.

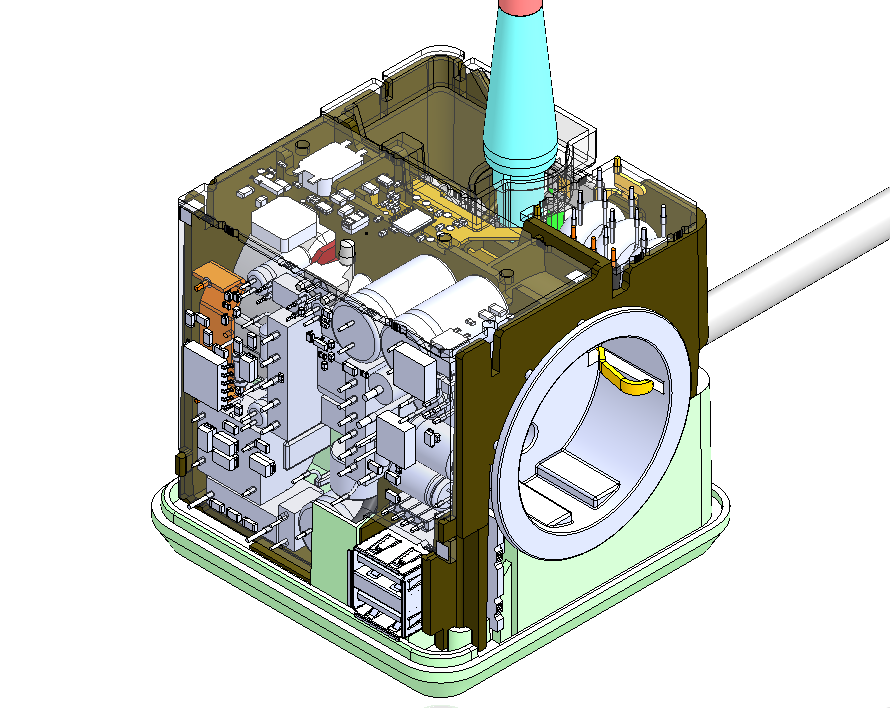

BRCK

BRCK approached True North to work with them to develop an IP68 rated aluminium die cast enclosure and internal framework for Supa BRCK – a connected, rugged micro-server bringing internet access and cloud computing to remote parts of East Africa.

Initial design was supplied by BRCK. True North then developed the materials, sealing mechanism, fasteners and adhesives for the 29 component assembly

We began production in September 2017, supplying DDP to BRCK’s assembler in Taiwan.

Despite facing numerous challenges together they have never let me down in more than 8 years of working together. It’s a true partnership and they never forget who the client is and what we need”

Chris Butler, Cronapress